The occurrence of flow interruption during the use of concrete pumps is definitely a problem for users. So why does flow interruption occur and what can be done to solve it? Today, I will share with you the solution to the problem of interruption.

1. Shorten the commutation time and accelerate the operating speed of the main cylinder piston at the beginning of commutation.

2. Adopting electric proportional control constant power plunger pump. By increasing the displacement of the main oil pump, the distribution valve can quickly change direction, reducing the time from changing direction to starting to push the concrete.

3. Two proximity switches are installed in the water tank between the oil cylinder and the concrete cylinder. The starting and ending points of the tapping port are set according to the displacement of the main oil pump, the cylinder diameter and stroke of the main oil cylinder. The distance between the proximity switches is usually 5% to 10% of the total stroke, and corresponding adjustments are made according to the actual situation of the concrete pump.

Concrete transfer pump is a device that uses pipelines to transport concrete, used for the transportation and supply of concrete in the construction of reinforced concrete structures. It is widely used in high-rise or super high-rise building projects, tunnel and bridge construction. The use of concrete conveying method can not only reduce costs, but also save construction time and standardize the construction site.

By studying the changes in the technical condition of concrete pumps during use, necessary maintenance and upkeep operations can be carried out before mechanical parts reach their ultimate wear or malfunction, which can extend the service life of concrete pumps, eliminate hidden dangers, prevent accidents, and ensure the smooth progress of pumping operations.

Below, based on the work experience of technical personnel, we will summarize the key maintenance and repair parts and contents of concrete delivery pumps in use, in order to guide customers of mechanical concrete delivery pumps in their operation and use

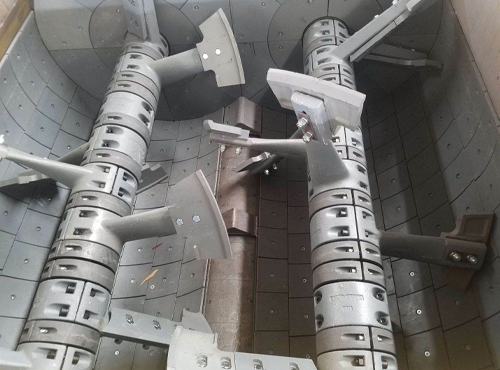

Taking HBT concrete delivery pump as an example, its hydraulic system includes four parts: main pump oil system, distribution valve oil system, mixing oil system, and lubrication system. The maintenance and overhaul of the hydraulic system is the key to the maintenance of concrete conveying pumps, mainly including the following points:

1. Hydraulic oil is a power transmission medium, as well as a softener and coolant. When selecting, consideration should be given to the working conditions, surrounding environment, and role of the hydraulic system. Hydraulic oil should have appropriate viscosity, good lubricity, good oxidation resistance, and good cleanliness. The normal hydraulic oil temperature is between 20 ℃ and 60 ℃, with a high temperature limit of 70 ℃. When draining hydraulic system oil, it is recommended to do so while the hydraulic oil is warm, so that the dirt in the hydraulic oil can be discharged with the oil: the oil should be drained as much as possible to prevent mixing of new and old oil. After draining the oil, rinse the accumulated material in the system with low viscosity hydraulic oil first, and the hydraulic oil must contain anti-corrosion agents to prevent rusting of the metal surface just after releasing the hot oil. The oil pump and oil motor should be replaced with hydraulic oil after disassembly and maintenance in case of malfunction. Every aspect of hydraulic oil management and use must prevent oil contamination. Hydraulic oil drums should be placed separately and covered with tarpaulins to prevent dust and water, and each drum should be fully loaded to prevent the formation of condensation water.

The main system oil filter and return oil filter of the hydraulic system should be regularly checked for blockages. If blockages are found, all oil filters should be cleaned or replaced with filter elements.

2. The main reasons for hydraulic oil tank contamination are:

(1) Dust on the construction site.

(2) The oil tank is small, and the hydraulic oil does not settle sufficiently before entering the oil pump again.

(3) The oil volume of the hydraulic system is low, and the turnover frequency increases accordingly. Pollutants cause an increase in the grinding of the hydraulic system. The mesh oil filter on the inlet pipe head of the hydraulic oil tank should be cleaned regularly to ensure that the oil pump can always suck in sufficient hydraulic oil.

Address: No. 818, Jingshi Road, Jinan, China

Tel: 0086-531-87453566

Fax: 0086-531-87453566

Postal Code: 250306

Email: sdjkgroup@163.com

jianke3566@163.com